in the present industrial landscape, the pressure is mounting. firms face the dual obstacle of optimizing operational effectiveness although simultaneously demonstrating a tangible motivation to environmental sustainability. frequently, the main focus falls on substantial-scale initiatives – renewable Vitality adoption, squander reduction programs, or source chain optimization. nevertheless, important gains can usually be present in the main points, specially within the parts that form the spine of electrical and Digital devices. Cable crimp connectors, Primarily All those from dependable copper connector brands, play a important role. selecting connectors based entirely on initial Value can result in a cascade of hidden costs and environmental burdens down the road. Conversely, prioritizing sturdiness isn't nearly longevity; it's a strategic choice that instantly translates into reduced source intake, decreased routine maintenance fees, and enhanced operational trustworthiness – a acquire-gain for both of those the balance sheet as well as Earth. This exploration delves into why tough cable connectors are An important ingredient of modern, sustainable industrial procedures.

Table of contents:

Material Matters: the inspiration of Longevity

Engineered for Endurance: The Role of Structural design and style

Extending the Lifecycle: an extended-Term viewpoint on cost savings

Resource Conservation: far more Than Just metallic

Delivering Enduring price: Gains over the Chain

materials issues: the inspiration of Longevity

The lifespan and trustworthiness of a cable connector get started at by far the most basic level: the fabric It can be made out of. The choice of material dictates its resistance to environmental stressors, its structural integrity with time, and eventually, how commonly it will require alternative.

the strength of large-toughness Aluminum: even though numerous metals are Employed in connector production, superior-energy aluminum alloys supply powerful rewards in certain demanding programs. Notably, their inherent resistance to corrosion is an important variable. In environments characterised by superior humidity, salinity (coastal or maritime programs), or exposure to industrial chemical substances, connectors made out of inferior components can speedily succumb to rust and degradation. This corrosion don't just compromises the Bodily framework but will also degrades electrical effectiveness, leading to possible failures and mandatory substitute. significant-high quality aluminum alloys, having said that, sort a protective oxide layer, enabling them to withstand these harsh ailments for prolonged intervals. This would make them extremely perfectly-suited to very long-expression out of doors installations, renewable Strength infrastructure, and difficult industrial options the place longevity is paramount.

Structural balance and growing older: further than corrosion, the inherent stability with the picked content performs a crucial position in combating structural getting old. Connectors are subjected to mechanical pressure all through set up (crimping) and during their operational life because of vibration, temperature fluctuations, and Bodily managing. large-good quality products, engineered for balance, resist deformation, micro-fractures, and embrittlement after a while. This makes sure the connector maintains its structural integrity and clamping drive, preventing intermittent connections or comprehensive failures that necessitate premature substitute.

Comparative Lifespan Analysis: when put next to some commonly used products like standard metal or specified grades of brass, carefully chosen and taken care of higher-power aluminum alloys can offer you top-quality longevity, especially in corrosive environments. when copper is an excellent conductor normally desired (numerous seek out a reliable Copper connector supplier Because of this), specialized aluminum alloys can provide a greater equilibrium of longevity, pounds, and corrosion resistance for precise structural and environmental troubles. The decision is not about conductivity alone, nevertheless the holistic overall performance in excess of all the lifecycle. picking out resources specifically for their endurance properties demonstrates a deeper dedication to decreasing the replacement cycle, which can be inherently much more sustainable. Less Recurrent replacement usually means a lot less mining, refining, and processing of Uncooked components in excess of the operational lifespan on the gear or set up.

Engineered for Endurance: The function of Structural layout

product choice lays the groundwork, but subtle structural structure transforms opportunity longevity into trusted overall performance. the best way a connector is engineered immediately impacts its capacity to kind and keep a secure, small-resistance link, minimizing the necessity for servicing and alternative.

Precision Interfaces (DIN Standards): Adherence to proven requirements, which include DIN 74 for particular connector sorts, signifies a determination to precision engineering. These standards dictate crucial Proportions and tolerances for that connector's interface. A specifically produced interface ensures a cosy, secure in shape Along with the corresponding terminal or conductor. This significant diploma of in good shape minimizes the likely for micro-actions caused by vibration or thermal biking, which can result in loosening, amplified Call resistance, warmth era (sizzling spots), and possibly dangerous electrical arcing. A link that stays tight involves a lot less Repeated inspection and eradicates failures attributable to weak mechanical healthy, therefore extending its useful daily life and reducing affiliated servicing labor.

Mechanically sturdy Crimping Zones: The crimp place is the place the connector physically joins the cable conductor. The design of this zone is crucial for extended-time period reliability. Connectors engineered with substantial mechanical toughness in the crimping barrel make certain a stable, gasoline-limited relationship when adequately crimped. This sturdy design withstands the numerous forces utilized during set up with no cracking or deforming excessively. additional importantly, it maintains consistent stress on the conductor strands after a while, blocking strand breakage, pull-out, or even the ingress of moisture and contaminants that might degrade the connection. a solid, trusted crimp is basic to preventing electrical failures and the following want for connector substitute.

Adaptability and Waste Reduction: Connectors built with wide adaptability for several cable measurements or styles within a specified vary present another delicate sustainability gain. Using a connector which will reliably accommodate slightly unique conductor diameters or insulation thicknesses (inside its rated capacity) minimizes the probability of making use of an improperly sized portion, which can result in lousy connections or squandered parts. In addition it simplifies stock management for large projects, cutting down the quantity of SKUs needed and minimizing prospective obsolescence or squander due to specification improvements.

Extending the Lifecycle: a protracted-time period Perspective on cost savings

The real worth of a sturdy connector emerges when considered throughout the lens of its complete lifecycle. concentrating only within the upfront obtain value ignores the significant downstream costs associated with Recurrent replacements.

evaluating substitute Cycles: take into consideration a standard industrial application. typical, reduced-high-quality connectors might have to have inspection and opportunity substitution every number of years, or all the more often in harsh environments. In contrast, a substantial-longevity connector, built with top-quality elements and style, could realistically very last noticeably lengthier, Most likely matching the lifespan on the tools by itself. Quantifying this difference – evaluating the normal substitution cycle of ordinary connectors versus the extended lifespan of quality kinds – reveals a powerful financial argument.

Cumulative Charge Savings (further than the portion): Every single substitution occasion incurs expenses far exceeding the cost of the connector by itself. These incorporate:

oLabor: Technicians' time for diagnostics, removal, and set up.

oDowntime: misplaced output or operational capacity while repairs are made.

oLogistics: Transportation costs for new areas and likely for personnel.

oMaterials: the expense of the alternative connector and any involved consumables.

When multiplied around hundreds or 1000s of link points in a significant facility or undertaking, and recurring over a number of substitute cycles prevented, the cumulative discounts come to be substantial. This Total price of Ownership (TCO) viewpoint Evidently favors durable parts.

lessening Rework and challenge Delays: In important engineering or development projects, connector failures all through commissioning or early operation can cause costly rework and substantial delays. making use of connectors known for their dependability within the outset minimizes this hazard. visualize the effect on a renewable Vitality farm or maybe a manufacturing plant rollout if dozens of connections are unsuccessful prematurely – the troubleshooting energy and plan disruption can dwarf the Preliminary Value difference of using higher-top quality components. longevity interprets directly into challenge certainty and dependability.

source Conservation: extra than simply Metal

The environmental benefits of sturdy connectors prolong over and above simply just making use of a lot less Uncooked content after a while. lessening the replacement frequency triggers a favourable cascade effect across several useful resource streams.

lessened producing Footprint: each individual connector produced requires Electricity for extraction, processing, production, and ending. much less replacements mean substantially fewer cumulative energy intake and less involved emissions (greenhouse gases, pollutants) through the manufacturing procedure over the process's lifetime. In addition, it signifies a lot less scrap metal created during manufacturing and disposal.

Minimized Packaging squander: Connectors are usually packaged for defense and identification. although necessary, packaging contributes to squander streams. Halving the quantity of replacements required right halves the involved packaging squander (cardboard, plastic) produced about the operational interval.

decreased Transportation Emissions: less substitute cycles directly translate into less transportation runs needed to provide new parts to web-site, In particular critical for giant-scale industrial assignments or geographically dispersed infrastructure. This reduction in logistics exercise lowers the general carbon footprint affiliated with servicing and maintenance.

Increased Electrical power Efficiency: lousy or degrading connections show greater electrical resistance. This resistance causes Strength loss in the shape of heat (I²R losses) and might cause voltage drops, most likely impacting devices performance. Stable, lower-resistance connections preserved above lengthy periods as a result of durable connectors contribute to overall process Power performance, reducing operational Vitality waste.

offering Enduring worth: Gains Across the Chain

The adoption of strong cable connectors provides tangible benefit not only environmentally, but in addition strategically to organizations as well as their consumers.

reduce routine maintenance Burden for Bulk customers: For initial devices brands (OEMs) or process integrators taking care of big fleets of equipment or comprehensive installations, extending the upkeep cycle of parts like connectors instantly lowers their ongoing support and warranty expenditures. This interprets into enhanced profitability and possibly more competitive provider choices.

Alignment with Sustainability traits: Increasingly, industries are struggling with regulatory pressure and industry demand for environmentally dependable products and solutions and functions. Specifying and making use of resilient components that reduce waste aligns with company sustainability aims and satisfies the increasing expectation for eco-certified or environmentally aware industrial pieces. firms are actively trying to find suppliers, which include attempting to find a responsible Copper connector producer or vendors of other resilient content alternatives, who can aid these initiatives.

Increased brand name popularity: firms that prioritize large-high-quality, strong factors sign a commitment to dependability and extensive-time period worth. picking out suppliers known for their durable and environmentally regarded items can enrich the end-person's brand impression, positioning them as responsible and good quality-targeted entities inside their own individual markets. It demonstrates a dedication that goes past the surface stage, embedding sustainability into the very material of their functions.

The standard cable crimp connector, generally forgotten, presents significant financial and environmental Rewards. concentrating beyond the Preliminary obtain rate highlights the importance of durability for extended-time period effectiveness and sustainability. Choosing connectors built with high-toughness products like aluminum, precision engineering, and a center on lifecycle performance can greatly cut down substitution frequency. This lowers complete possession expenditures as a result of discounts in labor, downtime, and logistics, even though conserving assets, minimizing waste, and reducing the carbon footprint tied to manufacturing and transportation.attaining these Rewards needs partnering with producers who prioritize longevity and source performance. organizations like website N.I.U ELEC layout Cable Crimp Connectors with sturdiness being a core basic principle, providing solutions that enrich reliability while supporting environmental objectives. Choosing strong connectors isn’t just a choice—it’s a strategic financial investment in creating a extra sustainable long term.

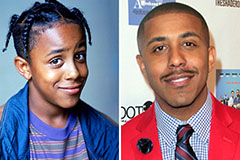

Marques Houston Then & Now!

Marques Houston Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!